Solutions

Fully automated detection whether using the benchtop, integrated or standalone solutions

ThruWave designs, builds, and sells proprietary mmWave imaging systems, image reconstruction software, and data analytics software, enabling our customers and end users to measure key process variables and improve the accuracy, efficiency and safety of their operations.

Detect illegal and hazardous items being transported through the mail.

- Detect illegal and hazardous items including firearms, tobacco, and drugs being transported through mail and postal channels

- Offered as a standalone solution or can be integrated with existing infrastructure, such as conveyors, sensors, material handling, and warehouse management systems

- High-throughput

- Automated detection

- See inside packages to illuminate hidden items

- Completely automated - does not require a human operator

- Can evaluate all parcel types, including envelopes and flats

- Can detect thin items, such as mylar

- Human-safe without bulky lead shielding or regulatory headaches

- Offered as a standalone solution or can be retrofit to existing conveyor infrastructure

Detect quality defects and anomalies in cartons before they propagate through your network.

- Quality control detection on inbound, outbound, and return processes

- Detect short shipments, count errors, damage, empty boxes, fraud, and leaks

- Offered as a standalone solution or can be integrated with existing infrastructure, such as conveyors, sensors, material handling, and warehouse management systems

- High-throughput

- Automated detection

- See inside packages to illuminate hidden items

- Detect errors missed by cameras, weigh scales, and scan tunnels

- Unlike cameras, sees inside boxes

- Unlike weigh scales, identifies fraudulent items of the same weight

- Self-scaling to new SKUs and defects

- Scan and evaluate 100% of cartons without slowing down your workflow

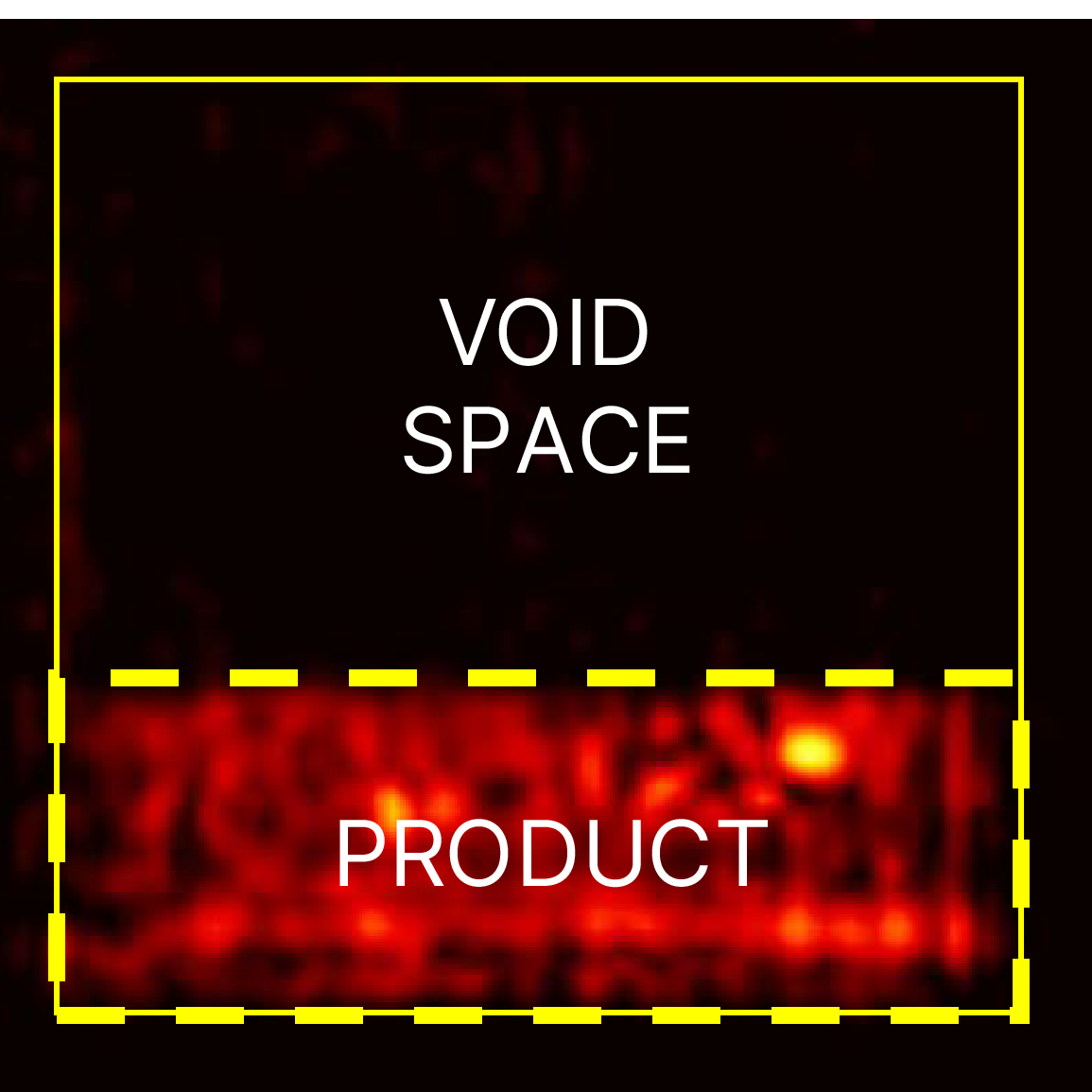

Inline void space and box fill detection.

- Determines box fill / void space without the need for opening the box

- Provides data for outbound shipment efficiency improvement

- Track box fill with web-based dashboard and divert underfilled boxes

- Offered as a standalone solution or can be integrated with existing infrastructure, such as conveyors, sensors, material handling, and warehouse management systems

- High-throughput

- Automated detection

- See inside packages to illuminate hidden items

- Current inline solutions cannot accurately detect box fill and void space

- Scan and evaluate 100% of cartons without slowing down your workflow

Benchtop Inspection System

Out of the box inspection solution that fits on a benchtop.

- Single item scanner with simple, turnkey operation

- Fits easily on a benchtop or desktop

- Automated analytics in real time for a variety of applications

- Perfect for facilities without existing conveyor infrastructure

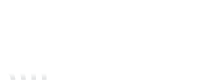

Standalone Inspection System

Turnkey inspection solution with included conveyor and

integrated divert mechanism.

- Can scan parcels such as mail and boxes in bulk

- Automated sorting solution

- Conveyor and integrated divert mechanism included

- Automated analytics in real time for a variety of applications

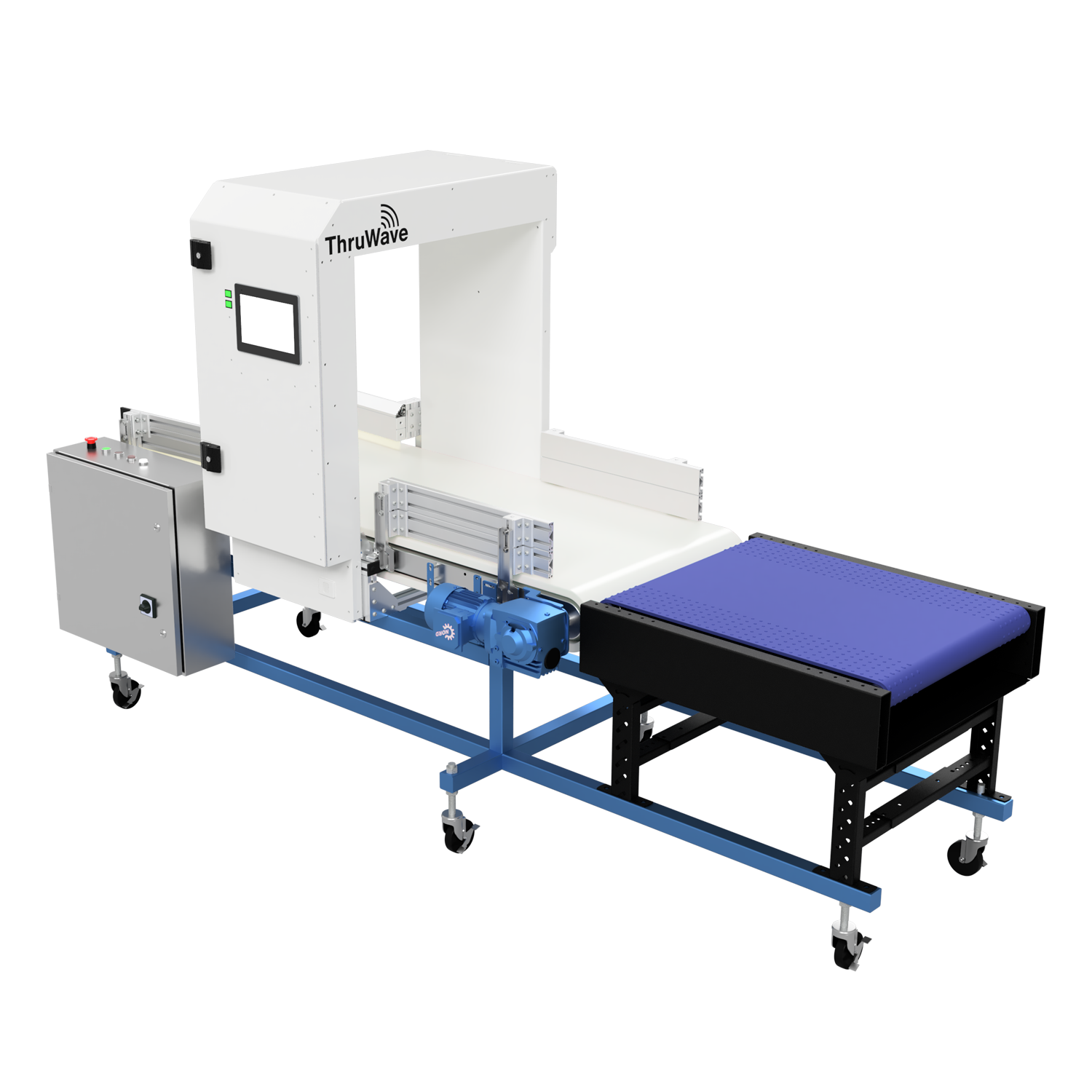

Integrated Inspection System

Retrofits to your existing material handling infrastructure.

- Small footprint for ease of installation

- High-throughput scanning of boxes and cartons

- 600 ft / min, 4 boxes / sec

- Retrofits around existing conveyor belt

- Can integrate to downstream sorting mechanism

- Automated analytics in real time for a variety of applications

Customer Success Stories

Improve Outbound

Packaging and Distribution

Problem: imperfect dimensioning and packing instructions mean boxes leave distribution facilities under-packed, wasting money on shipping and extra cardboard.

Current inline solutions, such as cameras or weigh scales, cannot accurately detect box fill and void space.

ThruWave’s solution improved the outbound packaging and distribution process for a leading manufacturer of specialty footwear and apparel by detecting void space and under-packed boxes.

ThruWave identified wasteful shipments of more than half of an 18-wheeler trailer full of air and more than an NBA basketball court of cardboard waste per day on average.

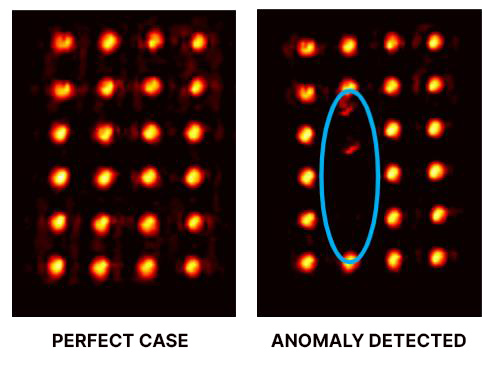

Detect case pack anomalies (missing bottles) in beverage manufacturing.

Problem: automated packing machines fail, meaning some cases do not have the correct number of bottles.

Currently leading solutions use ionizing gamma-rays or unreliable metal detection. These devices are high maintenance and require regular calibration.

In a production bottling environment quality test, ThruWavewas able to achieve improved detection performance compared to the leading solutions using human-safe technology, including a reduced number of false positives.

Detect anomalies in snack food distribution environment.

Problem: cartons of chip bags contain count errors or entirely wrong items.

Current solutions, such as weigh scales or random manual sampling, are expensive and not accurate enough, or require constant recalibration.

In a production snack food distribution environment, we not only kept up with the speed of high velocity sorting equipment, but we also vastly outperformed existing solutions.