Damage Detection

There's a new way to detect anomalies inside packages.

From the manufacturing stage through to the entire supply chain, there are millions of packages assembled with products that have the potential to leak, break or be compromised in other ways.

Until now, detecting these anomalies has been limited largely to the ability of the human eye to spot the issues. With ThruWave's ability to see through packaging, cardboard boxes and plastic totes, early detection for many of these cases is possible.

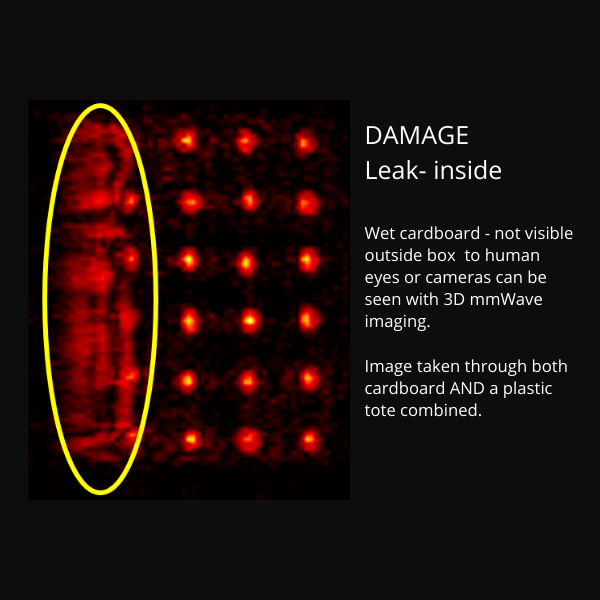

DAMAGED ITEM DETECTION

Broken items in packages can lead to reputational damage and unwanted chargebacks.

Identify individual damaged packaged product as it arrives or before you ship from your facility without requiring costly manual human inspection.

- Detect broken product in item level or case level packaging

- Detect leaking items in inside of totes or closed cartons

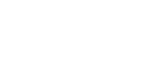

LEAK DETECTION

Leaking products can damage your warehouse infrastructure and lead to unhappy customers.

Our technology allows you to automatically detect leaks that may not even be possible to detect with the human eye so you can prevent problems before they become severe.

- Monitor inbound and outbound shipments for leaking items

- Divert leaking items as they appear during the manufacturing process

FOREIGN OBJECT DETECTION

Quality control is critical to prevent contamination of raw materials. Sometimes accidents happen and unexpected items end up in the products or the packages containing them.

Find objects that don’t belong before they make it to the next step in the manufacturing process or to the consumer.

- Detect metal and plastic in packaged food products

- Detect metal and plastic in raw dry goods like flour

- Avoid accidentally shipping tools (ie. box cutters) dropped in cases

- Avoid accidentally shipping high value equipment (ie. barcode scanners) dropped in cases